-40%

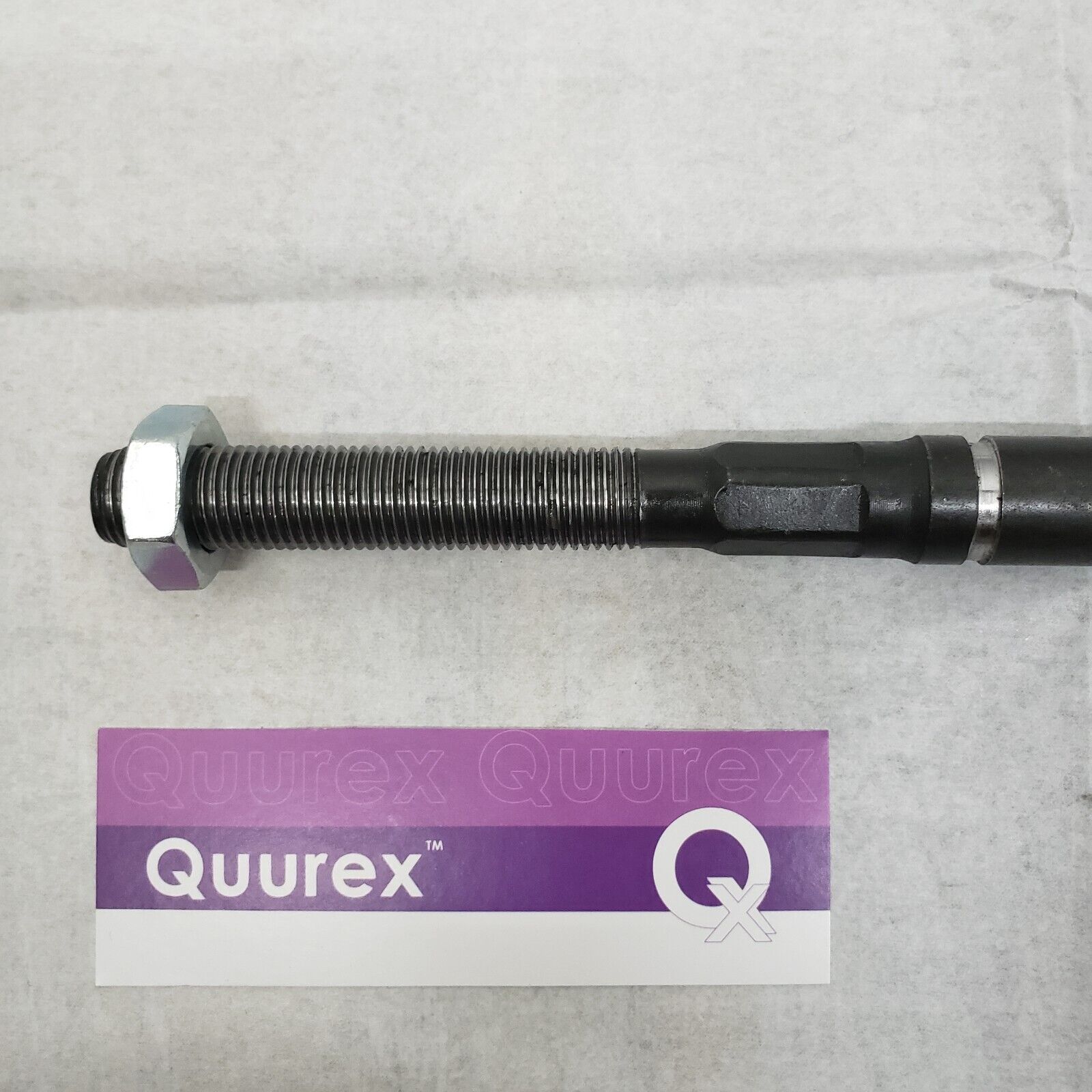

TESLA Model 3 Model Y Inner Tie Rod End Axial Joint 1044831-00-G 1044831-00-H

$ 39.6

- Description

- Size Guide

Description

TESLA MODEL 3, MODEL Y Inner Tie Rod End (Axial Joint) for- Tesla Model 3's manufactured on 01.2017 and newer

- Tesla Model Y's manufactured on 03.2019 and newer

Will replace

only

INNER TIE ROD ENDS (axial joints) of OEM part no 104483100G, 1044831 00 G, 1044831-00-G, 104483100H, 1044831 00 H, 1044831-00-H

Will fit both Front Right and Front Left.

Brand New Part.

PLEASE NOTE THAT:

***** Only Inner Tie Rod End, it does not come with complete Rack System. *********

If you need to replace the inner tie rod ends only without replacing the complete Rack and Pinion System.

Reverse engineered and manufactured to be exact same fit and to perform same as original OEM part.

Strong durable design with Plating for long life.

We will ship 1 part in a clear plastic bag. The part will have the necessary Class 8 locking Nut(s).

Will ship from Florida, USA.

It will be shipped as you see on the photos. There are no additional accessories, box or installation manual. Quurex Part No TS-A101.

This part has been manufactured for us (QUUREX) in a European Chassis Parts manufacturer, Disa Automotive.

-

Disa Automotive Manufacturing factory has IATF 16949, ISO 9001 and ISO 14001 quality certificates and following Functional Tests have been done on the product you are about to purchase;

Fatigue (Key Life) and Leakage test

Vibration test

Axial and Radial Spring Travel test

Initial Breakaway and Rotating Torque test

Welding Tensile Strength Test

Ball Pin Breakaway test

Ball Pin Pull Out and Push out test

Material Spectrometer checks

Material Microstructure Analysis

Salt Spray test

Technical Part Cleanliness test

These tests ensure the product has very high quality and a long life.

More over;

-

at Disa Automotive manufacturing factory, all production, maintenance, planning, purchasing, quality, product development human resources and project departments are compliant with VDA 6.3 process audit requirements.

-

Disa Automotive has the following procedures intact in its quality management system:

Statistical Process Control (SPC) studies (Cpk, Ppk, Cmk), Live SPC production control, Incoming goods control, Serial production process controls, Final controls, Measurement System Analysis (MSA), Design and Process FMEA studies, Effective 8D approach, Problem solving methodologies, Continuous improvement, Preventive and corrective actions, PPAP / PPA documentation according to customer requests.